Wrap Around Case . Your cases are formed and sealed around the product in continuous motion. The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. Products are loaded into die cut packaging which is then formed around the product and glue closed. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. No need for case former nor case sealer. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Using 30% less corrugated packaging than.

from www.maxcases.com

Using 30% less corrugated packaging than. Your cases are formed and sealed around the product in continuous motion. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. Products are loaded into die cut packaging which is then formed around the product and glue closed. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. No need for case former nor case sealer.

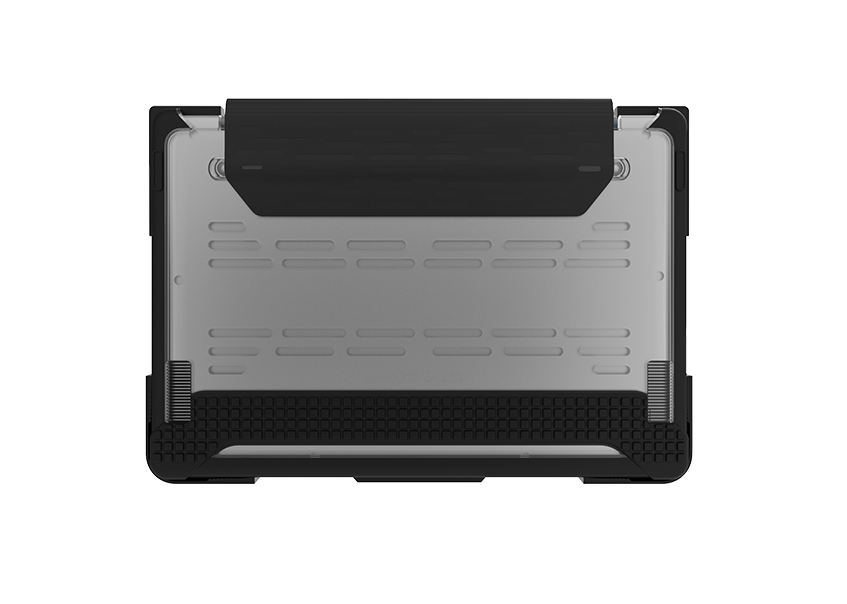

MAXCases Extreme ShellS Wrap Around Cases

Wrap Around Case Using 30% less corrugated packaging than. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. No need for case former nor case sealer. Products are loaded into die cut packaging which is then formed around the product and glue closed. The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. Your cases are formed and sealed around the product in continuous motion. Using 30% less corrugated packaging than. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint.

From enoline.solutions

Wrap around case packing Wrap Around Case Using 30% less corrugated packaging than. No need for case former nor case sealer. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. Products are loaded into die cut packaging. Wrap Around Case.

From www.propac.com

Arpac PC4500 Continuous Motion WrapAround Case Packer Professional Wrap Around Case No need for case former nor case sealer. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. The wrap around case packer places product from the side or top of the wraparound,. Wrap Around Case.

From www.propac.com

Arpac PC2500 Continuous Motion WrapAround Case Packer Professional Wrap Around Case Products are loaded into die cut packaging which is then formed around the product and glue closed. Your cases are formed and sealed around the product in continuous motion. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is. Wrap Around Case.

From www.propac.com

Arpac PC2500 Continuous Motion WrapAround Case Packer Professional Wrap Around Case Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. No need for case former nor case sealer. The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a. Wrap Around Case.

From www.youtube.com

Wrap Around Case Packing Applications Clearpack YouTube Wrap Around Case Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. No need for case former nor case sealer. Products are loaded into die cut packaging which is then formed around the product and glue closed. Using 30% less corrugated packaging than. Polypack’s innovative method of corrugated cardboard source reduction on wraparound. Wrap Around Case.

From www.campackaging.it

Innovative wraparound case by CAM CAM Automatic Machines Wrap Around Case The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. Using 30% less corrugated packaging than. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. Products are loaded into die cut packaging which is then formed around the product and. Wrap Around Case.

From www.abraa.com

Wholesale WrapAround case packer 91230 Supplier Wrap Around Case No need for case former nor case sealer. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Using 30% less corrugated packaging than. The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. Your cases are formed and sealed around the. Wrap Around Case.

From www.propac.com

nVenia Arpac PC2000 Intermittent Motion WrapAround Case Packer Wrap Around Case Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. No need for case former nor case sealer. Products are loaded into die cut packaging which is then formed around the. Wrap Around Case.

From www.packworld.com

Somic Wraparound case packer From SOMIC Packaging, Inc. Packaging Wrap Around Case Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. Using 30% less corrugated packaging than. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Your cases are formed and sealed around the product in continuous motion. No need for case former. Wrap Around Case.

From www.ecplaza.net

Wrap Around Case Packer 15 Case Per Min Guangzhou Vanta Packing Wrap Around Case The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. Using 30% less corrugated packaging than. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Products are loaded into die cut packaging which is then formed around the product and glue. Wrap Around Case.

From www.pcmachinery.com

Cermex wrap around case packer model SW22.40 with glue closure PharmaCos Wrap Around Case Using 30% less corrugated packaging than. Products are loaded into die cut packaging which is then formed around the product and glue closed. Your cases are formed and sealed around the product in continuous motion. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Wrap around case packers are designed to. Wrap Around Case.

From leadpackaging.com

Wrap Around Case Packer Lead Packaging Wrap Around Case Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. Your cases are formed and sealed around the product in continuous motion. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. No need for case former nor case sealer. The wrap around. Wrap Around Case.

From www.astropackaging.com

Wrap Around Case Packer Wrap Around Case Packing Machine Wrap Around Case Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Using 30% less corrugated packaging than. Your cases are formed and sealed around the product in continuous motion. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. No need for case former. Wrap Around Case.

From www.maxcases.com

MAXCases Extreme ShellS Wrap Around Cases Wrap Around Case Products are loaded into die cut packaging which is then formed around the product and glue closed. Using 30% less corrugated packaging than. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging.. Wrap Around Case.

From scil-machinery.com

WRAP AROUND CASE PACKER SCIL Machinery Wrap Around Case Using 30% less corrugated packaging than. Products are loaded into die cut packaging which is then formed around the product and glue closed. The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. No need for case former nor case sealer. Polypack’s innovative method of corrugated cardboard source reduction on. Wrap Around Case.

From www.youtube.com

VersaWrap® continuousmotion Wrap Around case packer YouTube Wrap Around Case Using 30% less corrugated packaging than. No need for case former nor case sealer. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Products are loaded into die cut packaging which is then formed around the product and glue closed. Wrap around case packers are designed to perform the erecting, loading. Wrap Around Case.

From www.inemur.com

Wraparound case packing INEMUR Wrap Around Case Your cases are formed and sealed around the product in continuous motion. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Wrap around case packers are designed to perform the erecting, loading and closing sequence all within one machine footprint. Products are loaded into die cut packaging which is then formed. Wrap Around Case.

From www.astropackaging.com

Wrap Around Case Packer Wrap Around Case Packing Machine Wrap Around Case The wrap around case packer places product from the side or top of the wraparound, harness style, or tray blank. Your cases are formed and sealed around the product in continuous motion. No need for case former nor case sealer. Polypack’s innovative method of corrugated cardboard source reduction on wraparound cases is a proven approach to sustainable packaging. Using 30%. Wrap Around Case.